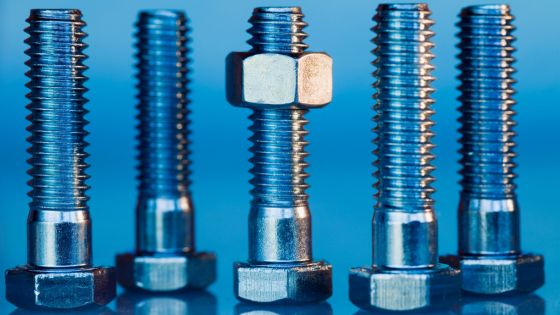

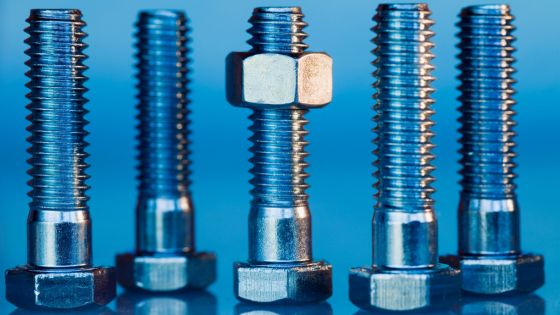

When it comes to building and construction, the integrity of small components can make all the difference in the durability and safety of a structure. Among these small yet critical components, fastener bolts play a pivotal role. Their design, particularly the threads, is essential for providing the necessary grip and tension to hold various materials together. It’s these spiraling grooves that translate rotational force into linear movement, ensuring parts are pulled tightly together. The effectiveness of bolt threads can be seen in everything from the towering skylines of cities to the cars one drives—everywhere, their precision holds the world together.

The Basics of Bolt Thread Design

Bolt threads are the continuous ridges on the shaft of a bolt that spiral around its circumference. These threads are the defining feature of a bolt, allowing it to secure materials together with a nut. The design of these threads is a complex science that balances thread spacing, depth, and angle to create a secure fit. A bolt’s thread design is not a mere accident; it is the result of careful engineering to ensure maximum strength and load distribution.

Thread Patterns and Their Applications

Not all threads are created equal. Different thread patterns serve distinct purposes and environments. For example, fine threads are often used in applications requiring high precision, while coarse threads are chosen for their ease of use and robustness in construction settings. Understanding the difference between these patterns is crucial for selecting the right bolt for the job. The choice of thread pattern affects not only the assembly process but also the long-term maintenance of the connection.

Materials and Coatings for Enhanced Performance

Fasteners bolts aren’t just about shape and size; the material and coating also play a significant role in their performance. High-strength steel bolts are common in heavy-duty applications, whereas titanium or brass bolts are used where corrosion resistance is paramount. Coatings such as zinc or chromium add an extra layer of durability and resistance to elements. These coatings can also provide a measure of lubricity, which facilitates tighter and more secure fastening.

The Significance of Thread Standards

Standardization in thread design is key for ensuring compatibility and reliability across different applications. Industry standards dictate the thread size, pitch, and tolerance, making matching bolts with the right nuts and washers easier. This harmonization is vital for maintaining quality and safety in fastening solutions. Standards such as those set by the International Standards Organization (ISO) or the American National Standards Institute (ANSI) ensure that a bolt from one manufacturer can fit with a nut from another without issue.

Measuring and Specifying Bolt Threads

Precise measurement of bolt threads is critical for their function. Tools like calipers and thread gauges are used to measure thread dimensions accurately. When specifying a bolt, it’s important to mention the diameter, thread pitch, length, and grade to ensure that the correct bolt is used for the intended application. The accuracy of these measurements affects not only the strength and fit of the bolt but also its resistance to wear over time.

Choosing the Right Bolt for Your Project

Selecting the right bolt involves understanding the load it needs to bear, the environmental conditions it will face, and the materials it will be fastening. Whether you’re dealing with screws and bolts or bolt fasteners, it’s essential to consider all these factors to ensure a secure and long-lasting fastening. The right bolt will reduce the need for maintenance and potential failure.

In conclusion, fastener bolts are fundamental in various industries, from construction to automotive manufacturing. Their threads may seem like a minor detail, but they are engineered with precision to provide a reliable hold in countless applications. As explored, the industry of bolt threads is rich with detail and complexity, which underscores the importance of choosing the right type for every task.