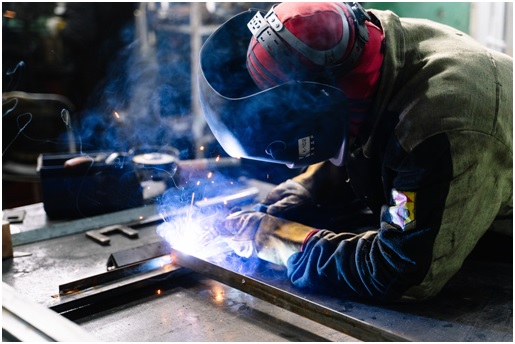

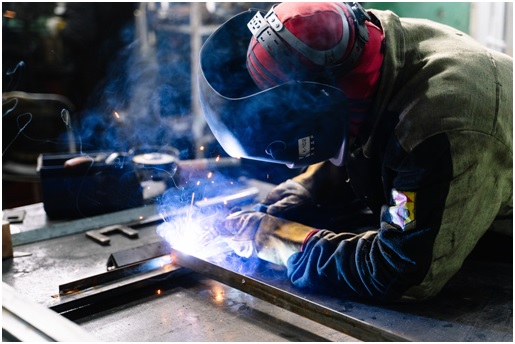

MIG welder use for MIG welding that is a popular choice for metalworking projects, but it can be dangerous if you need to learn how to do it properly. In this article, we’ll discuss some of the essential safety tips that will help keep you and your employees safe while working with this type of equipment.

Some of the common hazards and risks associated with MIG welding include the following:

- Burns: The intense heat and bright light generated by the welding arc can cause burns to the skin and eyes.

- Electric shock: The high electrical currents involved in MIG welding can result in electric shock if proper safety precautions are not followed.

- Fires and explosions: Welding can produce sparks and hot slag that can ignite flammable materials, leading to fires and explosions.

- Noise-induced hearing loss: The loud noises produced by welding equipment can cause permanent hearing loss if adequate ear protection is not worn.

- Respiratory problems: Welding can produce harmful fumes and gases irritating the respiratory system and potentially leading to long-term health problems.

It is taking proper safety precautions when MIG welding is essential to prevent accidents and injuries. That incorporates wearing the right individual defensive gear (PPE), setting up the welding region appropriately, setting up the weld cautiously, and following safe welding rehearses. By keeping these rules, you can guarantee a free from even a hint of the harm work area while MIG welding.

Make sure the work piece is properly secured

When welding, it’s important that the work piece is secured correctly. That can be done in a number of ways:

- Use a vise, clamp, or other secure methods to hold it in place. Vices are good because they allow you to make adjustments easily and quickly, but they should also be used with care so that they don’t tighten too much (which could cause burns). Clamps can be handy if you need something temporary or if your work area isn’t big enough for an entire clamps’ worth of material; however, these can also cause skin damage if applied too tightly. Always use caution when using this technique! If working on an assembly line with several pieces at once, consider using a specialized clamping system such as those made by Hobart Corporation, which provides more excellent stability than standard clamps while still allowing each piece its own space within the assembly line itself.

Personal Protective Equipment for MIG Welders

Personal protective equipment (PPE) is important to MIG welding’s protection. It is critical to wear the proper PPE while welding to shield yourself from the different dangers and dangers related to the interaction.

A portion of the sorts of PPE that MIG welders ought to consider wearing include:

- Helmet or face shield: A helmet or face shield is essential for shielding your head and face from the severe intensity, glorious light, and hurtful UV and IR radiation created by the welding circular segment. A few unique Helmet or face shield choices are accessible, including auto-obscuring head protectors, inactive caps, and flip-front caps.

- Welding gloves: Welding gloves shield your hands from consumption and electric shock. They ought to be made of an intensity-safe material and fit cozily to consider legitimate skill.

- Protective clothing: It is essential to wear protective clothing while MIG welding to protect your skin from burns and heat. That may include a flame-resistant jacket or overalls, long sleeves, and pants.

- Earplugs or earmuffs: The noisy clamors delivered by welding hardware can cause hearing misfortune while perhaps not appropriately safeguarded against. It means quite a bit to wear earplugs or ear covers to preserve your hearing while at the same time welding.

- Steel-toed shoes: Steel-toed shoes are essential for protecting your feet from falling objects or debris that may be present in the welding area. They can also provide additional protection in case of an accidental drop of the welding equipment.

It is essential to wear all of the necessary PPE while MIG welding to ensure your safety and prevent accidents and injuries.

Clean your MIG gun regularly.

• Clean your MIG gun after every use.

• Use compressed air or a shop vacuum to clean the gun.

• A good cleaning will help reduce the risk of overheating and corrosion, damaging your machine and making it unsafe to use.

• Take Aluminum Mig welder

MIG welding is safe when you follow proper practices and procedures.

MIG welding is safe when you follow proper practices and procedures. Safety is important for your health and the health of others. You will be safe while working with MIG welders if you follow reasonable safety procedures.

If you don’t follow safety procedures, then it’s possible that someone could get injured as a result of your lack of awareness or carelessness in performing specific tasks (i.e., holding a torch too close to yourself).

Conclusion

MIG welding is one of the safest methods to fabricate metal parts with mig welder. It only sometimes involves high pressure, so you don’t need special equipment or training. However, some things you should know before starting your next project all have to do with safety! You can make sure you stay safe by following these tips and practices.